Amazing Tips About What Is PLC And PCB

Difference Between Microcontroller And PLC

Decoding the Alphabet Soup

1. What's the Difference Between a PLC and a PCB, Really?

Ever find yourself staring at a bunch of acronyms and feeling like you're trying to decipher ancient hieroglyphics? Yeah, me too. Today, let's untangle two particularly perplexing ones: PLC and PCB. They might sound similar, but they play completely different roles in the world of electronics and automation. Think of it like this: one's the brains of the operation, and the other is more like the nervous system.

So, what exactly are we talking about? PLC stands for Programmable Logic Controller. PCBs, on the other hand, are Printed Circuit Boards. Both are crucial components in countless devices, but their purposes and functionality are worlds apart. Let's dive in and explore what makes each of them tick. We'll look at where you might find them in action and why they're essential to modern technology. No more acronym overload!

Imagine you're controlling a massive factory assembly line. You need something reliable, robust, and easily reprogrammable to handle all those moving parts and sensor readings. That's where a PLC comes in. It's a specialized computer designed for real-time control of industrial processes. Think of it as the foreman yelling commands at the machines, except way more efficient and less prone to coffee breaks.

Now, envision the inside of your phone or your computer. All those tiny components need to be connected in a precise and organized way. That's the job of a PCB. It's a board with conductive pathways etched onto its surface, acting like a highway system for electrical signals. Without PCBs, our devices would be a chaotic mess of wires and solder.

A Comprehensive Guide To Understanding PLC Components

Programmable Logic Controllers (PLCs)

2. Diving Deeper into the World of PLCs

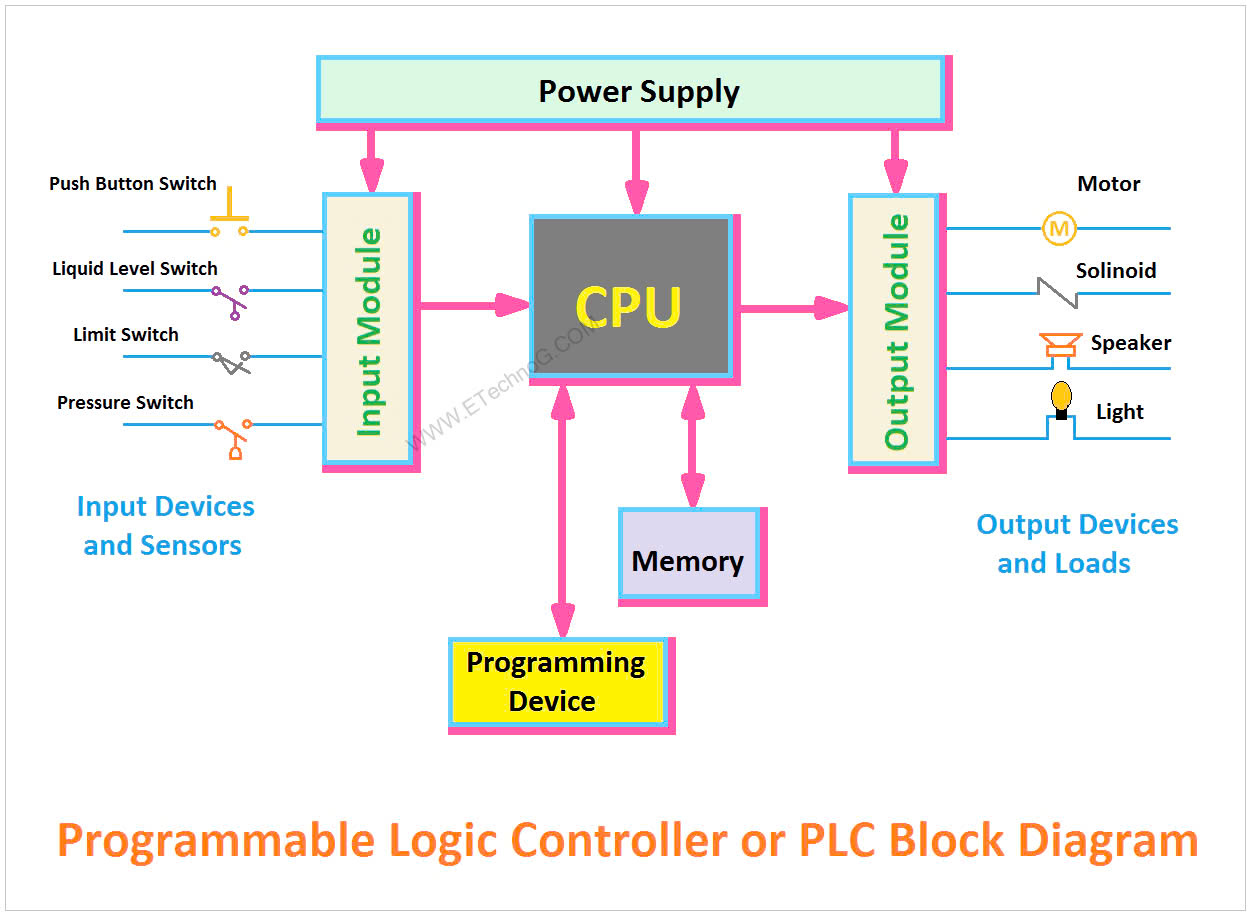

Okay, let's get a little more specific about PLCs. At its core, a PLC is a small computer that's been ruggedized to withstand harsh industrial environments. We're talking about things like extreme temperatures, vibrations, and electrical noise. Unlike your desktop PC, a PLC doesn't run Windows or MacOS. Instead, it runs a specialized operating system designed for real-time control and monitoring.

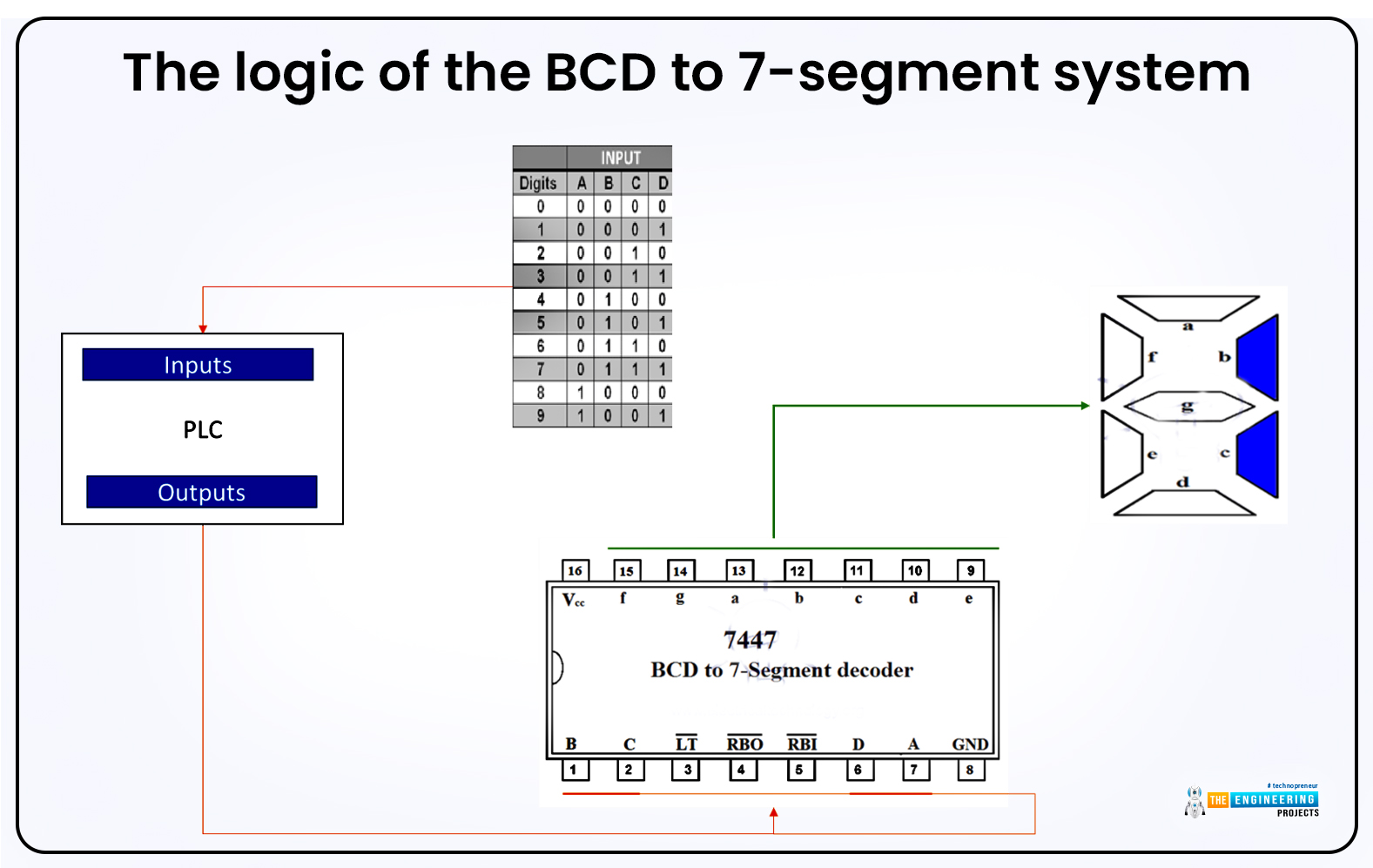

PLCs use a programming language, often ladder logic (which looks a bit like electrical schematics), to define the control logic. This logic tells the PLC how to respond to inputs from sensors and switches and how to control outputs to things like motors, valves, and actuators. It's like writing a recipe for a machine to follow, except instead of ingredients, you're dealing with voltages and currents.

The beauty of a PLC is its flexibility. You can easily reprogram it to adapt to changing production requirements. Need to add a new step to the assembly line? Just tweak the program. Need to change the timing of a process? Again, just a few lines of code. This programmability is what makes PLCs so valuable in industrial automation. Imagine having to rewire an entire control system every time you wanted to make a change! It would be a nightmare.

You'll find PLCs in all sorts of industries, from manufacturing and oil and gas to water treatment and power generation. They're used to control everything from simple on/off switches to complex robotic systems. So, the next time you see a massive machine churning out products, remember there's probably a PLC humming away inside, making sure everything runs smoothly. It's the unsung hero of the industrial world.

Printed Circuit Boards (PCBs)

3. Exploring the Intricacies of PCBs

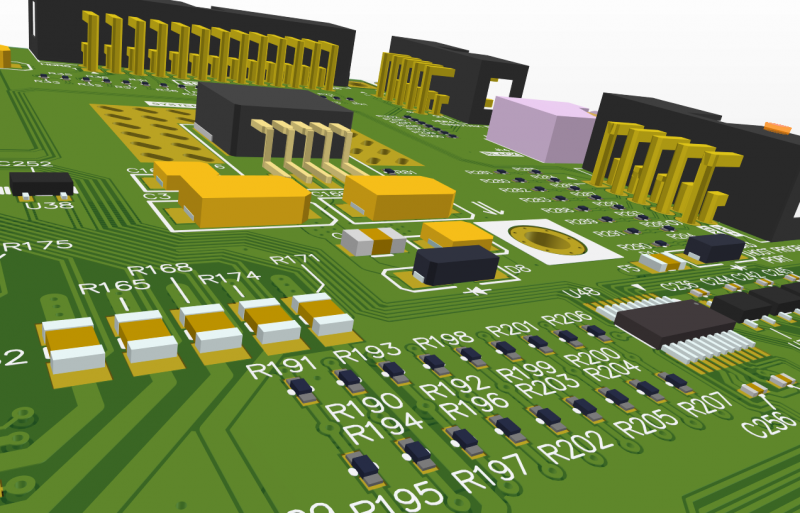

Now, let's shift gears and talk about PCBs. As we mentioned earlier, a PCB is a board that physically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. It's essentially a super-organized wiring diagram made permanent.

PCBs come in all shapes and sizes, from simple single-layer boards to complex multi-layer boards with dozens of layers. The more layers, the more complex the circuit and the more components that can be packed onto the board. This miniaturization is what allows us to have incredibly powerful devices in incredibly small packages. Think about fitting all the electronics of a smartphone onto a single PCB! It's a marvel of engineering.

The process of designing and manufacturing PCBs is quite involved. It starts with creating a schematic diagram of the circuit, then using specialized software to lay out the components and route the traces (the conductive pathways). This layout is then transferred to a copper-clad board using a photolithographic process. The unwanted copper is etched away, leaving behind the desired circuit pattern. Finally, the board is drilled, plated, and tested.

Without PCBs, modern electronics as we know it would be impossible. They provide a reliable and compact way to connect components, reduce noise and interference, and improve overall performance. From your phone and computer to your car and appliances, PCBs are everywhere. They're the backbone of the electronic world.

Key Differences at a Glance

4. PLC vs. PCB

To recap, here's a quick comparison of PLCs and PCBs:

- PLC: A specialized computer for real-time control of industrial processes. Think factory automation.

- PCB: A board that physically supports and electrically connects electronic components. Think your phone's internal organs.

- Purpose: PLCs control machines; PCBs connect electronic components.

- Environment: PLCs are designed for harsh industrial environments; PCBs are more delicate.

- Programming: PLCs are programmed with specialized languages; PCBs are designed with CAD software.

So, while both PLCs and PCBs are essential components in modern technology, they serve very different purposes. One is the brains of the operation, and the other is the nervous system. Understanding the difference between them is crucial for anyone working in electronics, automation, or engineering.

It's also worth noting that sometimes PLCs themselves contain PCBs. The PLC's internal circuitry, like its processor and memory, are all housed on a PCB. So, in a way, a PLC is a system that uses a PCB to function. This highlights how interconnected these technologies are.

The world of electronics is always evolving, with new technologies and components emerging all the time. But PLCs and PCBs will continue to play a vital role for the foreseeable future. They are the foundation upon which so much of our modern technology is built. Appreciating their function and how they differ is key to understanding the digital world we live in.

PLC Là Gì? Vai Trò Của Trong Tự động Hóa Công Nghiệp

Real-World Examples

5. Where You'll Find PLCs and PCBs in Action

Let's bring it all home with some real-world examples. Think about a bottling plant. PLCs control the entire process, from filling the bottles to capping them and labeling them. They monitor sensors that detect bottle levels, control the speed of the conveyor belts, and ensure that everything runs smoothly and efficiently. Without PLCs, the plant would be a chaotic mess of spills and bottlenecks.

Now, consider your car. Under the hood, there are several PCBs controlling various functions, such as the engine management system, the anti-lock braking system, and the airbags. These PCBs receive signals from sensors and actuators, and they use that information to make real-time decisions about how to control the car's systems. Without PCBs, your car would be a lot less safe and efficient.

Even your home is filled with devices that rely on PLCs and PCBs. Your washing machine uses a PLC (or a simpler microcontroller) to control the wash cycles. Your television contains multiple PCBs that process the video and audio signals. And your smart thermostat uses a PCB to control the temperature in your home.

So, as you can see, PLCs and PCBs are everywhere, often working together behind the scenes to make our lives easier and more convenient. They are the unsung heroes of the modern world.

FAQ

6. Your Burning Questions Answered

Still have some questions buzzing around? Let's tackle some common queries:

Q: Can I use a PLC instead of a regular computer?

A: Well, technically you could, but it wouldn't be a great idea for everyday tasks. PLCs are designed for industrial control, not web browsing or word processing. They lack the software and hardware for general computing.

Q: Are PCBs expensive to manufacture?

A: It depends on the complexity. Simple, single-layer PCBs are relatively cheap to produce, but complex, multi-layer boards can be quite costly, especially in small quantities.

Q: What happens if a PLC fails?

A: That's why redundancy and safety measures are built into systems controlled by PLCs! Depending on the application, a PLC failure could halt production, damage equipment, or even create a safety hazard. Proper maintenance and backups are crucial.

Q: Can I repair a PCB myself?

A: Unless you're an experienced electronics technician with the right tools and knowledge, probably not. PCBs are delicate, and it's easy to damage them further. Best to leave it to the pros.